Thor Hawk Ind. Supply Co., Ltd.

Thor Hawk offers custom-made PTFE Belt and various material conveyor belts, as well as nylon rubber power transmission belts for industries across all sectors. We also act as agents for multiple European and American industrial brands, providing customers with a diverse range of choices and sharing project experience to help clients find solutions.

Find a Solution

Online Support and Service

You could consult online, there might be a time difference, you might need to wait for 48 hours. Thank you for your patient.

Conveyor Belt

What is a conveyor belt?

A conveyor belt is a mechanical device used in industrial and commercial applications to transport materials, goods, and products from one place to another.

Conveyor belts are usually composed of a belt and several rollers or drives, which can be powered by electricity, hydraulics, pneumatics, or other power sources.

What are the different materials for conveyor belts?

There are many options for conveyor belt materials, such as PVC, PU, silicone, rubber, PTFE fiberglass fabric, steel, plastic chain plate conveyor belts, modular mesh conveyor belts, and more.

The appropriate belt material is typically selected based on factors such as the working environment, operating temperature, conveying method, special requirements, etc. We recommend that you contact the general belt business team via email or phone to discuss the selection together.

What is the use of the conveyor belt?

Oil-proof conveyor belt/anti-skid conveyor belt/climbing conveyor belt/anti-acid and alkali conveyor/flame-proof conveyor belt/corrosion-proof conveyor belt/moisture-proof conveyor belt/oil-resistant conveyor belt/low temperature resistant conveyor belt/high temperature resistant conveyor belt/anti-static conveyor Bring and so on.

How to choose a suitable conveyor belt?

Choosing a suitable conveyor belt requires consideration of factors such as load, speed, transmission distance, environmental conditions, operating temperature, production efficiency, and product characteristics such as volume, weight, and shape.

For semi-automatic heat sublimation or heat transfer printing, recommended conveyor belt materials include endless felt belts or silicone-coated felt belts.

Conveyor Belt Design / Cleaning and Maintenance

How to design a machine?

The design of a machine should primarily focus on structural integrity, considering factors such as the diameter and shape of peripheral devices like rollers, as well as automatic tracking and edge adjustment systems. The consideration for slip and deviation will vary depending on the friction coefficient of different belts.

How to design the drive pulley and driven pulley?

The shape, width, and diameter of the drive pulley and driven pulley should be carefully considered, taking into account the material structure and thickness of the conveyor belt. Please contact the Thor Hawk sales team for a discussion on your design project.

How is the safety of conveyor belts ensured?

Ensuring the safety of conveyor belts requires comprehensive consideration in terms of design, installation, use, and maintenance. Design and installation should consider the reliability and safety of the conveyor belt, while using it requires adherence to operating procedures and protective measures. Regular inspection and maintenance of the conveyor belt are necessary. Safety measures for conveyor belts include installing protective covers, setting up emergency stop switches, conducting regular inspections and maintenance, and providing employee training, etc.

What are the reasons for conveyor belt deviation?

Conveyor belt deviation can be caused by factors such as unevenness of the belt itself, uneven loading, improper adjustment, insufficient tension, failure to adjust tension daily, lack of regular maintenance, or equipment malfunctions. Careful observation is required to identify the root cause before making improvements. During installation, the head and tail rollers, as well as the intermediate rollers, should be aligned as closely as possible on the same centerline and parallel to each other to ensure minimal or no deviation of the conveyor belt.

Does the conveyor belt require regular maintenance?

Yes, the conveyor belt requires regular maintenance. Regular maintenance ensures its normal operation, extends its service life, and reduces the risk of accidents.

Regular maintenance of the conveyor belt ensures its proper functioning, reduces downtime, prolongs its service life, and improves production efficiency and safety.

What are the considerations for conveyor belt maintenance?

Conveyor belt maintenance involves regular inspection of the belt's condition, cleaning away dust and debris, lubricating moving parts of the conveyor belt, and timely replacement of damaged components.

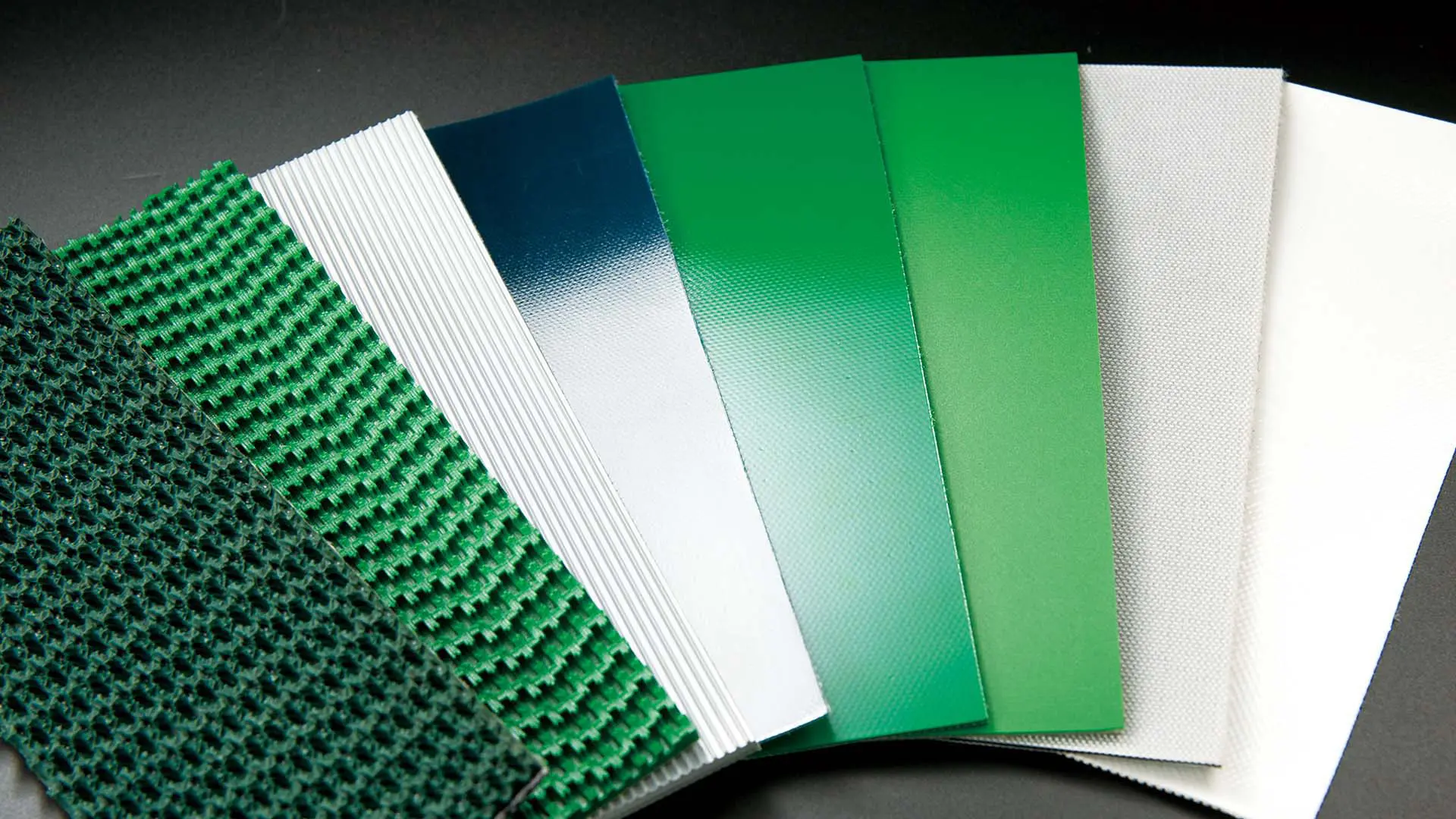

PVC / PU Conveyor Belt

Working temperature of PVC/PU belts:

Generally, PVC or PU belts have a working temperature of approximately 80°C. However, there are special PVC or PU belts available that could withstand temperatures up to 110°C. Please email or contact the Thor Hawk sales team to discuss further.

Surface options:

Smooth surface/Matte surface/Patterned surface/Diamond pattern/Grid pattern/Small dots/Cross pattern/Diamond pattern/Non-woven fabric, etc.

Special processing:

Accessories such as cleats, guide blocks, guide strips, skirts, etc., could be bonded.

Timing Belt

Type and material options for timing belts:

There are numerous types available for timing belts, and we could provide timing belts made of rubber or PU material. Please contact our Thor Hawk sales team via email or phone to provide the required information such as type, material, specifications, and quantity.

Could the timing belts be done with special or customized processing?

Yes, timing belts could be done with special processing or customization. It is possible to add PU or rubber cover to the timing belts, as well as bonded nylon fabric. Additionally, special processing such as adding guide blocks or performing punching could be done based on customer requirements.

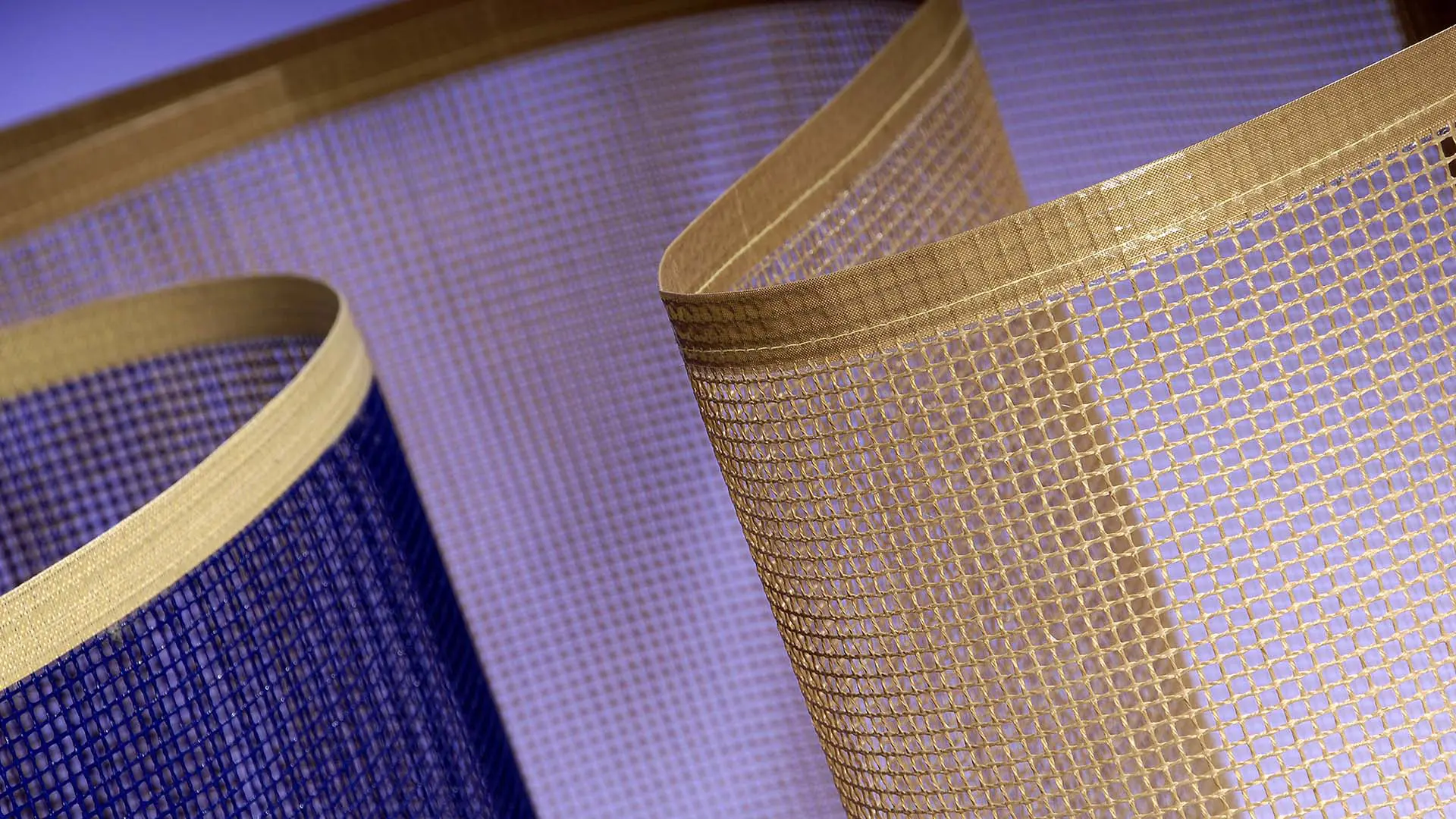

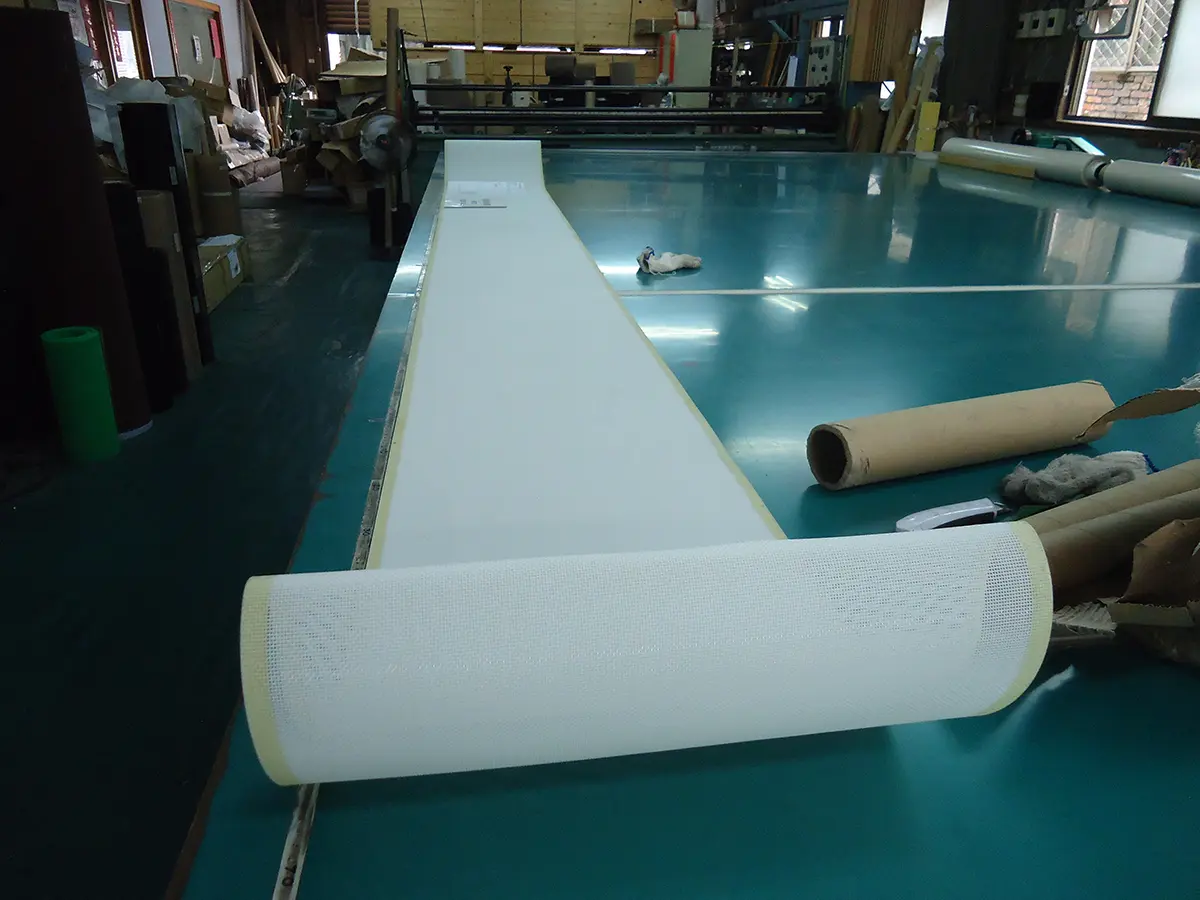

PTFE

Why use PTFE conveyor belts?

PTFE conveyor belts are used in high or low-temperature working environments. They are also suitable for environments that require resistance to sticking or chemical resistance. The main features of PTFE conveyor belts are excellent chemical resistance, good release properties, and the ability to withstand high working temperatures.

What is a PTFE conveyor belt made of?

PTFE conveyor belts are made by weaving glass fiber or Kevlar fiber and then coating them with PTFE.

What is the working temperature of PTFE belts?

For plain belts or mesh belts woven from glass fiber and coated with PTFE, the working temperature is approximately 260°C. If the belts are woven from Kevlar fiber and coated with PTFE, the working temperature is around 200°C. PTFE products can withstand temperatures as low as approximately -72°C.

Pulley/Roller design for PTFE belts

When using PTFE belts, the pulleys/rollers should have a flat design and not be center-crowned.

How to design PTFE conveyor belts?

The design of PTFE conveyor belts should consider variables such as the material being transported, weight, product, speed, etc. Please contact the Thor Hawk sales team to discuss and research together.

What are the tensile strength and load capacity of PTFE conveyor belts?

The tensile strength and load capacity of PTFE conveyor belts vary depending on the material and structure. Please contact the Thor Hawk sales team to discuss and research together.

Can endless PTFE belts be provided?

Thor Hawk could provide endless PTFE plain belts, but there are width and length limitations. Please email or contact the Thor Hawk sales team to discuss the dimensions.

Please recommend an anti-static belt.

Thor Hawk could provide anti-static belts. Please email or contact the Thor Hawk sales team to discuss your specific requirements for anti-static properties.

Options of PTFE plain belt thickness.

Thickness options for PTFE plain belts range from 0.075mm to 0.80mm. For more details, please contact the Thor Hawk sales Team.

Options of mesh size for PTFE mesh belts.

Mesh size options for PTFE mesh belts include 1x1 mm, 2x2 mm, 4x4 mm, 5x5 mm, 5x6 mm, 7x7 mm, and 9x9 mm. For more details, please contact the Thor Hawk sales team.

Steel Belt

Advantages of steel belts:

Steel belts have very low elongation and virtually zero backlash. They do not require lubricating oil. Steel belts do not generate airborne particles through friction, making them clean and suitable for use in cleanrooms.

They have excellent thermal and electrical conductivity, do not accumulate static electricity, and could achieve precise positioning and high repeatability.

Are there belts suitable for cleanroom environments?

If you require a belt for a cleanroom environment, it is recommended to consider steel belts. Please email or contact our Thor Hawk sales team, specifying the cleanroom classification requirements, so that we can discuss and explore suitable options.

What key points should be considered when designing steel belts?

When designing steel belts, factors such as belt thickness, diameter of the drive or driven pulleys, working temperature, maximum torque, belt speed, and acceleration need to be taken into account. Please feel free to contact our Thor Hawk sales team to discuss your specific design requirements.

Pulley design for steel belts:

Under normal circumstances, flat rollers should be used (avoid using crowned rollers to prevent the formation of stress concentration points). If you have specific requirements, please contact our Thor Hawk sales team for further discussion.

Transmission Belt

Options of transmission belts:

Depending on the specific design requirements, suitable materials for transmission belts could be considered, such as (1) timing belts, (2) rubber belts, (3) rubber nylon belts, (4) leather belts, (5) nylon composite fabric belts, (6) steel belts, and so on.

If you have small rollers that require high strength, could you recommend a suitable power transmission belt?

If you have very small roller diameters (8 mm) or knife edges, we highly recommend using Esband endless belts.

Accessories options

Options of belt guiding strip materials:

You have the option to choose from PVC guides, silicone guides, PTFE (Teflon) guides, and Kevlar guides.

Belt edge reinforcements options:

Options for belt edge reinforcements include PTFE film reinforcements, Kevlar fabric edge reinforcements, fiberglass fabric edge reinforcements, and glue edges.

Accessories Options:

You could choose steel studs and eyelet holes.

Joint Options:

finger joints/2 ply finger joints/Overlap/Butt joint/Clipper/Alligator/Alligator staple fastener//Peek spiral joint/steel spiral joint/spiral joint with Nomex fabric/Loop/castellated with pin/cable seam/woven joint, etc.

Explore Our Products

Thor Hawk is a professional company that provides high-quality conveyor belts and offers the best products and services to customers in various industries. Our conveyor belts are widely used in various fields such as material handling, automated production lines, warehouse logistics, food processing, pharmaceuticals, semiconductors, electronics, clothing, sewage treatment, and many others. Our main products include Teflon conveyor belts, rubber conveyor belts, PVC conveyor belts, PU conveyor belts, nylon fabric conveyor belts, silicone conveyor belts, timing belts, steel belts, wire mesh belts, plastic mesh conveyor belts, and many other materials. We could provide customized belts according to the requirements of customers. We have a group of professional and experienced technicians and production equipment to provide stable quality and quick delivery. Thor Hawk has abundant foreign supplier procurement resources and is an agent for European and American brands industrial products. We can provide customers with diversified choices and share project experience to help customers find better solutions. The principle of Thor Hawk team is based on integrity, focused on professionalism, and emphasizes service.

We firmly believe that only by providing stable quality and professional services could win the long-term trust and support of customers. If you have any needs regarding conveyor belts, please feel free to contact us, and we will be dedicated to serving you.

PTFE belt

> PTFE coated glass fabric

> PTFE coated kevlar fabric

> Baking sheets_PTFE tape_PTFE tape with lining

PVC conveyor belt

PU conveyor belt

Silicone belt

Transmission belt/Nylon fabric belt

Leather nylon belt

Rubber belt

Steel belt

> Robot arm steel tape

> Solar cell stringer belt

>Automatic packaging steel belt and other applications

> Steel belt with FDA grade

> Medical steel belt

> Steel mesh belt

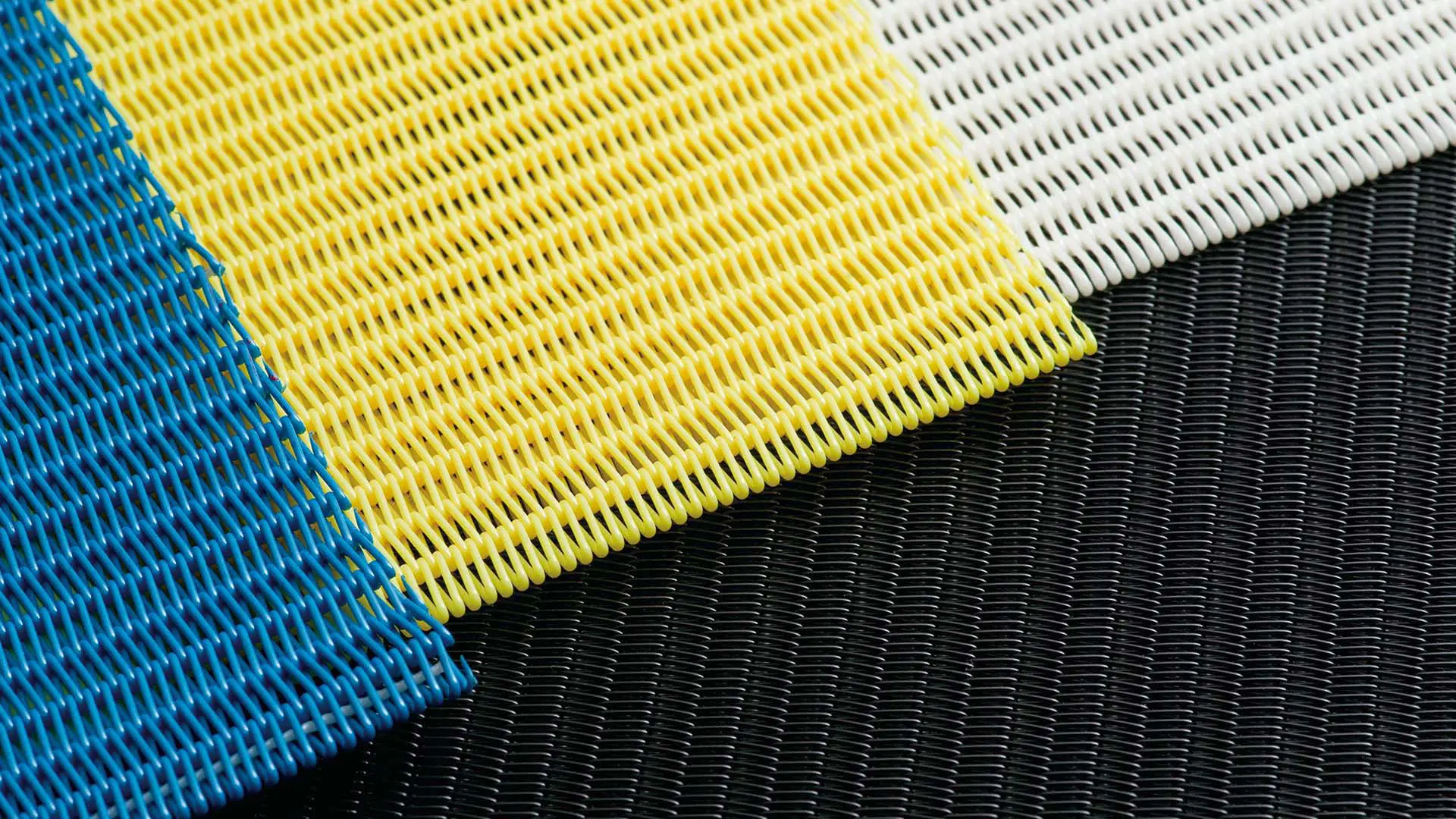

Polyester spiral belt / Plastic mesh woven belt

High temperature resistant endless felt

> High temperature resistant endless felt

> Ceramic fiber and Silica fabric

Other special industrial belts

Address:

No.21, Wuquan 8th Rd., Wugu Dist., New Taipei City 24891, Taiwan (R.O.C.)

tel: + 886 2 2299-9101 / fax: + 886 2 2298-8199

Copyright© 2025 通用皮帶企業有限公司 All rights reserved.